What Are Axial Flux Motors?

Axial Flux vs Radial Flux Motors Part 1

Everybody has read the headline “Axial Flux Motors are Taking Over the World!.”

Ok, maybe the headline should read, “Axial Flux Motors are Gaining in Popularity”.

So, what are axial flux motors and how are they different from regular motors?

Fundamental Design Differences

The main difference is the way the magnetic flux (magnetic field) flows in the motor.

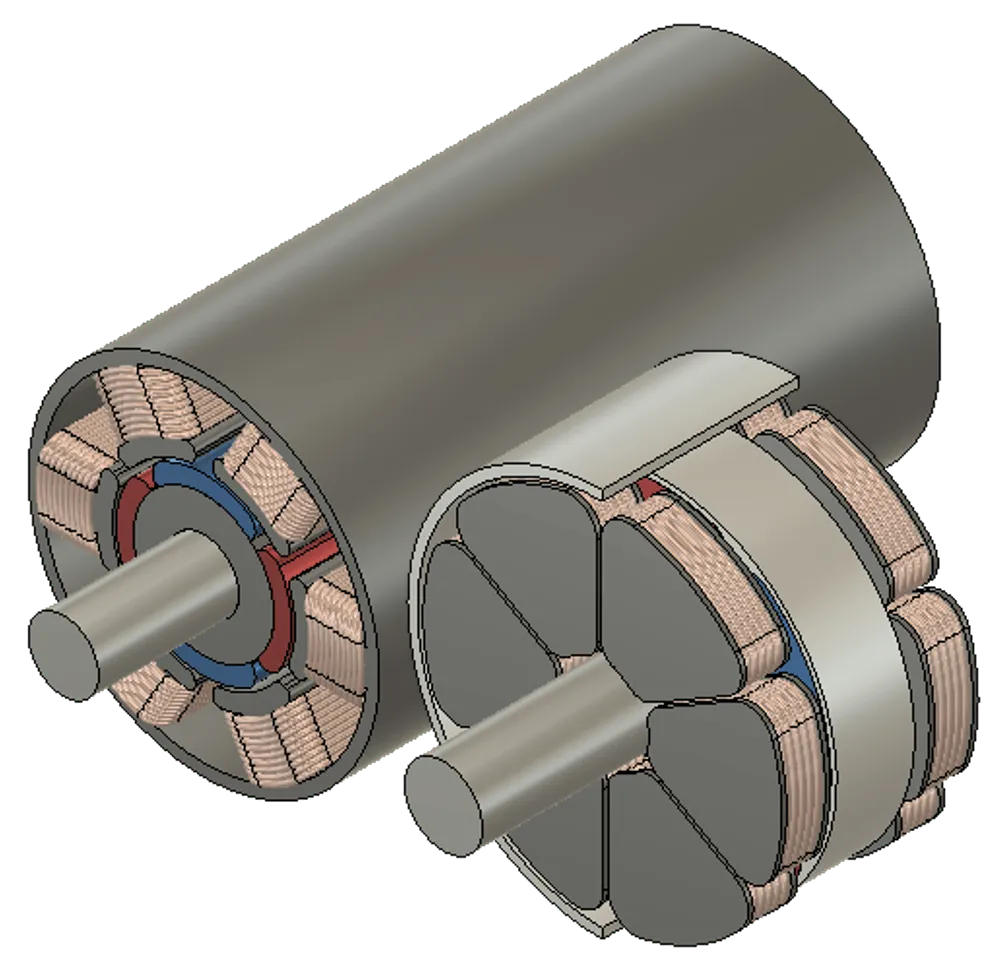

Radial Flux Motors

Radial flux motors have dominated the industrial and automotive landscape for a century, think of the conventional shaped motors you have already seen or interacted with. Starter motors, fan motors, air compressors, handheld drills, about every motor you have interacted with are radial flux.

In radial motors the magnetic flux flows perpendicular to the central shaft (axis). This means the flux flows outward from the central shaft (populated with magnets) then “radially” around a part of the outer case before returning to the central shaft.

They consist of two major parts that are cylindrical in design with a “Stator”(stationary), which is the part that surrounds the motor and usually is integrated into the case and the “Rotor” which has the shaft that sticks out of both ends. There are motors built in reverse and the case spins, but this is far less common.

Axial Flux Motors

Axial Flux motors were invented first but never really became popular. In axial flux motors the magnetic flux flows parallel to the central shaft “axially.”

Like radial flux, axial flux motors consist of a stator and a rotor(s). Generally, axial flux motors have rotors on either side and a stator in the middle, or vice versa (stators on the outside and rotor in the middle) creating a pancake or hamburger design with the stator being the burger and the rotors being the buns, or vice versa.

The magnetic flux flows from the rotor (bun) through the stator (burger) into another rotor. This creates a larger diameter motor, but it is much shorter and lighter than the radial flux motor. Axial flux motors are often called “pancake” motors because they look like a stack of three pancakes. You have interacted with pancake motors but did not know it. There are many sizes and variations, including one stator and one rotor like in CPAP machines and old reel to reel tape drives.

Performance Comparisons

Power Density and Efficiency

Axial flux motors offer superior power density—up to four times greater than radial counterparts depending on design. This means more power in a smaller, lighter package. The shorter, more direct magnetic flux path in axial flux motors contributes to the increased efficiency and reduced energy losses.

Torque Characteristics

Axial flux motors can deliver torque 30-40% higher than similar sized radial flux motors. This higher torque-to-weight ratio makes them particularly attractive for applications where space and weight constraints are critical. Also, axial flux motors control the torque more accurately which makes them popular for speed-controlled situations such as precision equipment and magnetic tape drives.

Cooling and Thermal Management

The flat design of axial flux motors provides a large, flat surface area for cooling, although there can be a high concentration of heat near the central shaft. Radial flux motors usually dissipate heat through the stator core and the thick iron outer case.

Manufacturing Considerations

Radial flux motors benefit from a mature manufacturing process and simpler assembly. In contrast, axial flux motors have typically been challenging to produce and often require CNC machining vs thin steel stampings.

Applications and Industry Adoption

Radial flux motors have dominated as indicated before due to their established design and manufacturing simplicity. However, axial flux motors are increasingly being used in applications such as:

· Electric vehicles, where their compact size and larger power density allow more space for other features

· Aerospace applications, where weight savings are critical

· Renewable energy systems like wind turbines

· High performance applications where power density matters (Formula E race cars)

Which is better?

Neither design is universally superior, and choice depends on applications. Radial flux is tried and tested and has higher RPM capabilities—ideal for many traditional applications. Axial flux, on the other hand, really shines in scenarios demanding maximum torque, efficiency, and power with minimal space and weight.

Why Multi-Rotor Axial Flux is a Better Option

Typically, to increase the RPM of axial flux motors, you reduce the diameter and stack several complete motors together to regain lost torque by using a smaller diameter motor. To further complicate the situation let us not forget the duplicate controllers which require synchronization and multiple cooling paths increasing weight.

With our motors, multiple rotors in a single case have several advantages.

We only need one controller and one cooling path but get the advantage of multiple motors stacked together.

We get the greater efficiency and torque of the axial flux rotors. And we can combine the advantages of both axial flux motors and radial flux motors by placing magnets on the outer circumference of rotors and around the shaft, increasing the overall magnetic flux usable for torque and reducing the number of windings not being used for active torque production.

Let me know in the comments what you think.

JC